Connecting rod assembly

Review

Description

Details

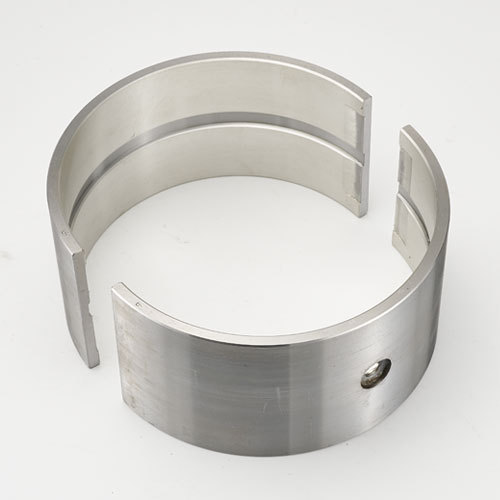

Constituent Part :Big-end bearing shell (upper bearing shell), Small-end bearing shell (copper sleeve,lower bearing inserts) , connecting rod bolt ,connecting rod nut and connecting rod body .

Material

35#,45#,QT600,40Cr or 42CrMoE for connecting rod body ;

Aluminium-magnesium Alloy and Babbitt Alloy for upper bearing shell ;

ZCuSn10Pb1,Aluminium-magnesium Alloy or Babbitt Alloy for lower bearing shell , 40Cr,35CrMoAlA or 42CrMoE forging for connecting rod bolt .

Integral cast aluminum-magnesium alloy bearing bush with high strength, low friction coefficient and long life

At the point of forced lubrication, the pressure bearing capacity of the whole machine is 5 times that of the babbitt bearing bush, and the service life is more than 3 times, and its special material performance can provide reliable operation guarantee for the crankshaft.

In a reciprocating piston type power machine and compressor, a connecting rod is used to connect the piston to the crank. Most of the connecting rods are steel parts, and the main part has a circular or I-shaped cross section, and there are holes at both ends. The hole is provided with a tin bronze bushing or a needle bearing for inserting the shaft pin to form a hinge. An important part of the connecting rod reciprocating piston compressor is connected to the piston and the crankshaft. Its function is to convert the reciprocating motion of the piston into the rotational motion of the crankshaft and transmit the force acting on the piston to the crankshaft to output power.

The connecting rod is also subjected to longitudinal and lateral inertial forces during operation. Therefore, the connecting rod operates under a complicated stress state. It is subject to both alternating tensile and compressive stresses and to bending stresses.